Bespoke Solutions

Orthos Projects Ltd offers and provides a bespoke service to meet the unique requirements of our clients of any given project. At Orthos we know that no two projects are ever the same. The expert application of CAD and technical engineering creates a plant with high integrity, innovative design and consistent quality.

Flexibility and versatility are essential in providing effective and viable engineered solutions to match specific process plant requirements. Our engineering expertise, production and process knowledge has enabled us to develop and satisfy a number of specialist applications including [but not exclusively] Plant Design Solutions, Materials Handling and Storage Solutions and Process Plant Solutions. Details on these services can be found below.

We understand and appreciate that to be successful you need to be adaptable, to meet client’s specific requirements. Included in all our designs and systems is many years of experience and knowledge, in the various disciplines required to deliver a first class service. This you cannot put a price on, it comes as part of the package free of charge!

Orthos Projects are a ‘One-Stop-Shop’ for all Bulk Solids, Raw Materials Handling and Process Plant Requirements!

On a number of occasions we have been commissioned by clients to undertake the design works for complete materials handling and processing plants. Following the obtaining of the necessary information required, we draft the initial layouts for discussion and once the plant layout is accepted and approved we’ll then produce a full set of detailed fabrication drawings using the latest AutoCAD drafting software, in which the client can issue to their chosen fabricators and suppliers

Orthos provides integration through the supply and installation of necessary materials handling components and equipment to complete a project supply. From specialised handling of friable products to the conveying of industrial abrasive materials, we supply materials handling and storage equipment to satisfy every eventuality including; Silos, Hoppers, Bunkers, Buildings, Belt Conveyors, Belt & Bucket Elevators, Pendulum Bucket Elevators, Pneumatic Conveyors, Vacuum Conveyors, Screw Conveyors, Bin Dischargers and many more.

Various materials of construction and finish are available such as galvansied, mild steel painted or powder coated or stainless steel dependent on application.

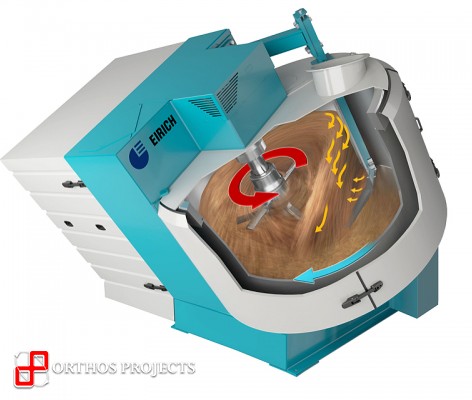

ORTHOS PROJECTS LIMITED process plant solutions encompass a diverse range of activities and extend across numerous industries.

In providing a unique approach to process design, construction and project management our engineering expertise, production and process knowledge can provide a range of services to meet any requirement. From the construction of new handling, storage and processing plants to the modification and remodeling of existing facilities, we offer a tailored approach dependent on the individual scope and requirements of each project which includes:

- Turnkey Supply

- Turnkey Solutions

- Design & Project Management

- Design & Engineering Service

- Process Automation & Control

- Mechanical & Electrical Installation

- Mechanical & Electrical Commissioning

- Process Equipment Supply

- Bespoke Solutions & Fabrications

Through our process engineering prowess and reputation we can deliver a diverse range of process solutions to both domestic and overseas markets. Our customer base extends to both major international companies and worldwide private sector clients all of which have benefited from our ability to adapt and tailor our services to meet the specific requirement of any given project.

Our solutions are diverse, tailored to suit the required scope of supply, ranging from individual items of plant and equipment provided for integration into an existing process to entire process plant.

In addition to our process plant solutions we can provide specialist fabrications inclusive of buildings, structural steelwork, silos, bins, hoppers, bunkers, fume and dust extraction ducting etc.

In providing a unique approach to process design, construction and project management our engineering expertise, production and process knowledge provides the range of services to meet many process application requirements, which includes:

- Batch mixing

- Continuous mixing

- Blending

- Granulating

- Agglomerating

- Pelletising

- Compacting

- Dispersing

- Drying

- Cooling

- Screening

- Sizing

- Size reduction

- Separating

- Grinding

- Weighing (batch & continuous)